The scia Magna 200 is a magnetron sputtering system used for precision wafer coatings of metals and/or dielectric layers up to 200mm diameter. Typical depositions include piezoelectric layers, optical coatings, and passivation layers.

This system is very versatile and can be suitable for a small scale R&D application, or configured into a cluster arrangement for mass production.

Principle:

- Magna 200 Magnetron arrangements:

- Single magnetron principle with rotating magnetic field. Mag. dia. > substrate dia. (left video)

- Confocal magnetron arrangement (up to 4). Mag. dia. < substrate dia., thus, substrate rotation required (right video)

- DRM 400 from Fraunhofer FEP with two concentric targets. Mag. dia. > substrate dia.

Features and Benefits:

- RF bias for conformity and stress control

- Excellent uniformity with rotatable substrate holder

- Helium cooling contact and electrostatic chuck (ESC) maintains low substrate temperatures

- High deposition rates with reactive sputtering in unipolar and bipolar mode

- Tunable film properties by adjusting energetic substrate bombardment and other parameters

- Co-sputtering with confocal arrangement of magnetrons

Applications:

- Temperature compensation films for TC-SAW devices (SiO2)

- Piezoelectric films with excellent and defined crystal orientation (AlN)

- Optical high- and low- refractive coatings (SiO2, TiO2, HfO2, ZrO2, Nb2O5 , Ta2O5)

- Electrical insulating films (Si3N4, SiO2, Al2O3)

- Co-sputtering of metals and alloys

Technical Specifications:

| SPECIFICATION | DESCRIPTION |

|---|---|

| Substrate size | up to 200mm |

| Substrate holder | Water-cooled, helium backside cooling contact Optional: RF bias Optional: electrostatic clamping Optional: substrate heating (up to 750C) |

| Substrate rotation | 0-20 rpm. |

| Sputter sources | Substrates ≤ 150 mm 250mm magnetron with rotating magnetic field, or, 125mm confocal magnetrons (up to 4) Substrates up to 200 mm 300mm magnetron with rotating magnetic field, or, Double Ring Magnetron (DRM 400) from Fraunhofer FEP |

| Sputter modes | Substrates ≤ 150 mm DC in uni- or bipolar pulse mode (up to 10 kW), and/or, RF (up to 3 kW, 13.56 MHz) Substrates up to 200 mm DC in uni- or bipolar pulse mode (up to 2 x 10 kW), and/or, RF (up to 6 kW, 13.56 MHz) |

| Typical deposition rate | SiO2: 90 nm/min (single) 7 nm/min (confocal) 180 nm/min (DRM 400) |

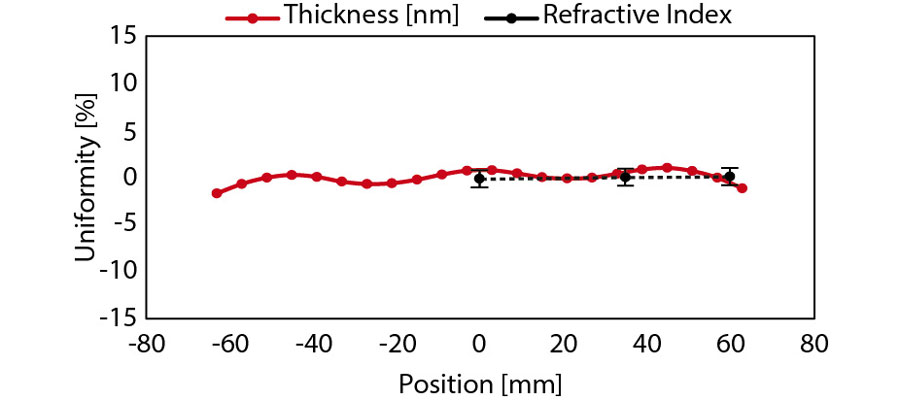

| Film Uniformity | ≤ 1.5 %* (single) ≤ 0.8 %* (confocal) ≤ 0.5 %* (DRM 400) *(σ/mean) |

| Base pressure | < 1 x 10-6 mbar |

| System dimension (W x D x H) | 2.70m x 1.10m x 1.60m, Single chamber with cassette handling (without electrical rack and pumps) |

| Configurations | Single chamber with single substrate lock lock or cassette handler Cluster system with up to 5 process chambers and cassette handler |

| Software interfaces | SECS II / GEM, OPC |