The scia Eva 200 is an electron-beam (e-beam) evaporation tool capable of depositing ultra-pure coatings on substrates up to 200 mm. The system holds up to 12 target materials in crucible-pockets, and can be configured with single wafer load lock or with fully automated cassette handling. The system also has a very small footprint and has an optional ion beam source that can be integrated for surface pre-cleaning.

Principle:

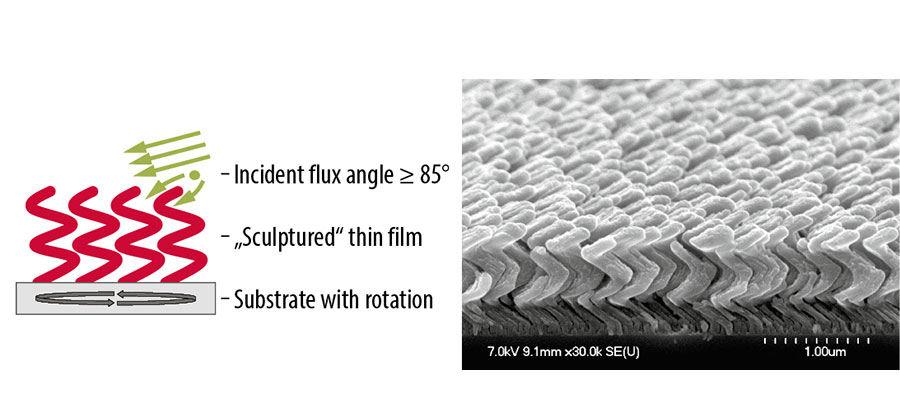

Electrons emitted from current running through a tungsten filament are accelerated to an e-beam by high voltage. A magnetic field deflects the e-beam so that it is focused into the crucible containing desired deposition material. The evaporation of this target material is deposited onto the substrate, which is rotatable and tiltable (to allow for glancing angle deposition – GLAD). An optional ion beam source can be used for surface pre-cleaning and/or deposition assist.

Features and Benefits:

- Substrate holder precisely tiltable and rotatable, defined angle of incidence adjustable

- High deposition rates for evaporation of high temperature materials and refractory metals

- Up to 12 evaporation materials in water-cooled multi pocket rotatable crucible

- Fully automatic cassette handling in variable cluster layouts including SECS/GEM communication

- Optional: ion beam source for pre-cleaning and deposition assist

Applications:

- Metallization of substrates

- Dielectric coatings

- Optical coatings

- Infrared-emitters for detection and spectroscopy for gas analyzer and smart applications

- Glancing angle deposition (GLAD) of nano-structured thin film layers for production of photo-electrodes for efficient fuel generation

Technical Specifications:

| SPECIFICATION | DESCRIPTION |

|---|---|

| Substrate size | Diameter: up to 200mm |

| Substrate holder | Cooling: Water-cooled, helium backside cooling contact Rotation: 5 to 20 rpm Tilt: in-situ from 0° to 180° in 0.1° steps Heating: optional |

| E-beam evaporator | 4 to 12 pockets on a cooled crucible |

| Ion beam Source | Optional: 120 mm circular RF source (RF120-e), or, 218 mm circular microwave ECR source (MW218-e) |

| Neutralizer | DC plasma bridge neutralizer (N-DC) RF plasma bridge neutralizer (N-RF) |

| Typical deposition rates | NiCr: 16 nm/min SiO2: 40 nm/min |

| Film Uniformity | ≤ 0.3 % (σ/mean) |

| Base pressure | < 5 x 10-8 mbar |

| System dimension (W x D x H) | 1.80m x 1.50m x 2.40m single chamber with single substrate load-lock (without electrical rack and pumps) |

| Configurations | Single chamber with single substrate load-lock or cassette handling, or, Cluster system with up to 3 process chambers |

| Software interfaces | SECS II / GEM, OPC |