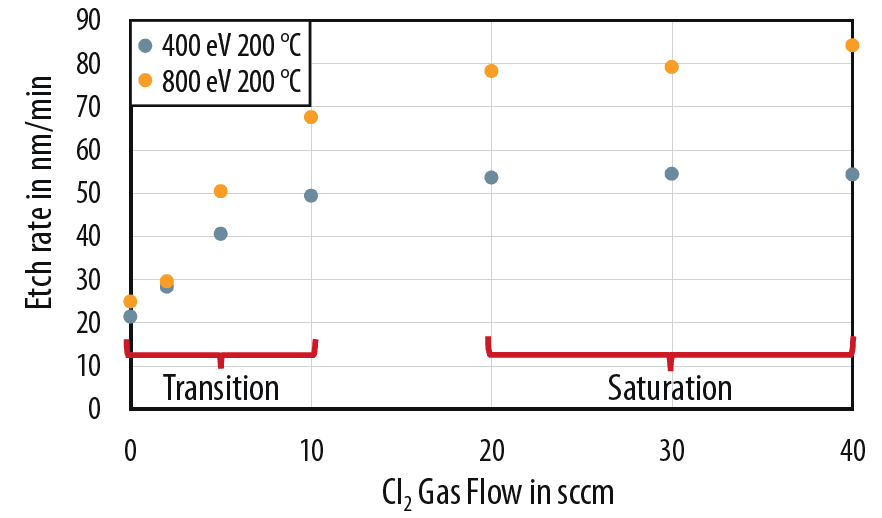

Chlorine-based CAIBE process can be used to dry etch III-V materials for various semiconductor and photonics applications. In such a high vacuum CAIBE process, Cl-based gas is added through a gas ring next to the wafer, in addition to Ar milling from the ion beam source. The reactive gas is absorbed on the surface and forms volatile etch products that is desorbed from the surface and pumped away. Wafer temperatures can be precisely controlled up to 300°C to handle the volatile byproducts.

The scia Mill systems are specially designed to handle Cl- and F- based processing in high-uptime, high volume manufacturing environments. That includes the proper hardware upgrades such as special coated turbo pumps, chamber heating jackets, and more. Meanwhile, we also offer a variation of the CAIBE system that have just as good of quality as a HVM system, but with the process and sample handling flexibility for a R/D environment.

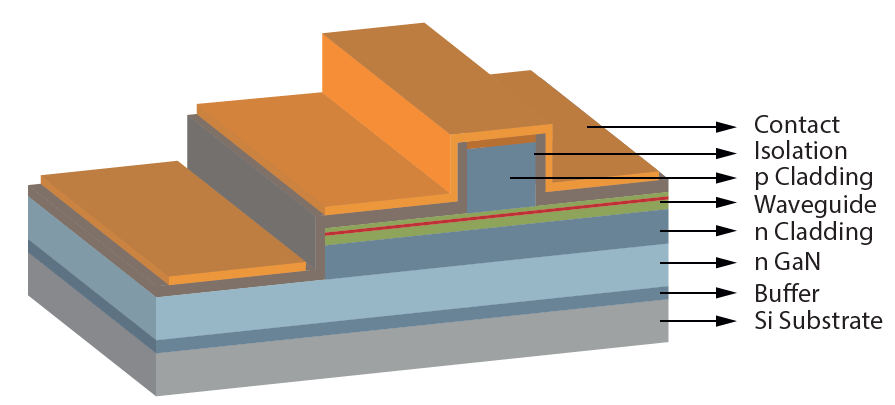

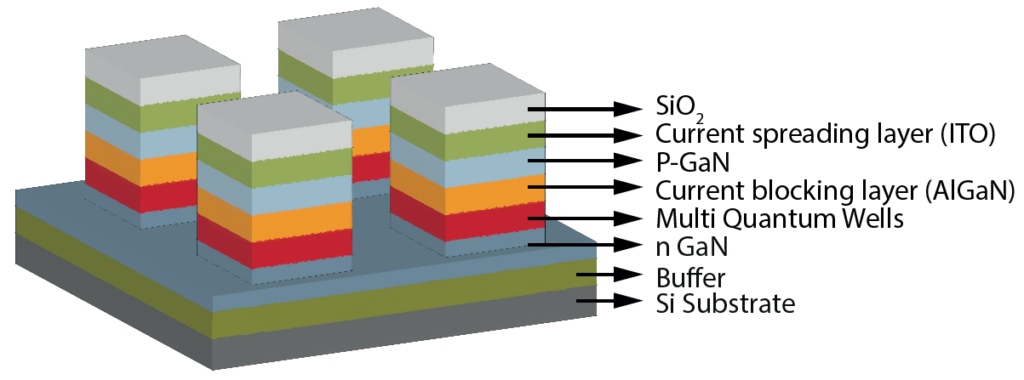

CAIBE is the preferred process when etching III-V materials that require very smooth sidewalls and precise control of sidewall angle 90° ± 1°. When etching laser facets, the scia Mill can achieve a front to back face angle difference of <1°. Our CAIBE systems can also be tuned to reach adequate selectivities while achieving good process results, for example, GaN:SiO2 of 7:1.

Our Cl CAIBE can be used for the following III-V materials, and more. Please reach out if you have a material in mind that is not listed here, but could benefit from a CAIBE system.

- GaN

- GaAs

- InP

- InAs

- AlGaAs

- InGaAs

- Other epi materials and multilayers…