Please reach out if you are unable to find suitable vacuum, plasma, and/or ion beam equipment for your application.

scia Systems’ experienced and qualified team is able to design and engineer a custom-made system that meets customers’ requirements. scia Systems is happy to collaborate and fulfill your needs.

scia Systems’ Expertise:

- Process development

- Design of models, layouts and drafts

- Software development and system control

- Complete media and electrical planning

- Documentation, CE-certification and risk analysis

- Internal manufacturing and assembling of core components

- Utilization of the whole technology portfolio of scia Systems

- Ion Beam Etching (IBE) – broad (full wafer) and focused trim (scanning spot size 5-30mm)

- Ion Beam Deposition (IBD) – with option of assist source (pre clean or DIBS)

- Magnetron Sputtering – co-sputtering up to 4 targets, reactive depositions, any substrates size or shape possible

- Plasma Enhanced Chemical Vapor Deposition (PECVD) – large area 300x200mm up to 750mm squares

- Reactive Ion Etching (RIE) – large area 300x200mm up to 750mm squares

- E-beam Evaporation – GLAD capabilities, reactive deposition, high uniformity coatings

- Dry cleaning – UHV + thermal desorption, plasma treatment possible as well. Precise precleaning of large substrates

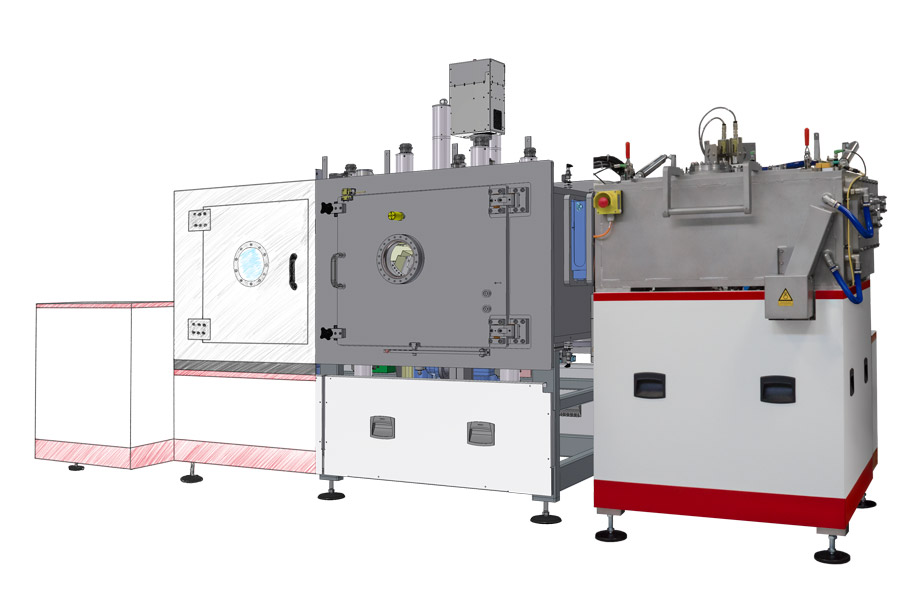

- Single chamber, Cluster or Inline systems available

- Various loading configurations: cassette, single substrate load lock or manual loading

- Versatile systems capable of R&D and/or high-throughput production environments

Please browse our website for our expertise in existing tooling. scia Systems has had numerous projects of creating such custom tooling that have been developed from R/D scale tools into reliable 24/7 high volume manufacturing systems, installed across the largest fabs in the world. In fact, some of our standard tooling today originated from these custom requests from customers.