The scia Finish 1500 is designed for high precision surface form error correction of optical elements in the field of ion beam figuring (IBF) on substrates up to 1.5m.

It is suitable for high volume 24/7 operation with its fast pumping times and high removal rates of the ion beam source.

Principle:

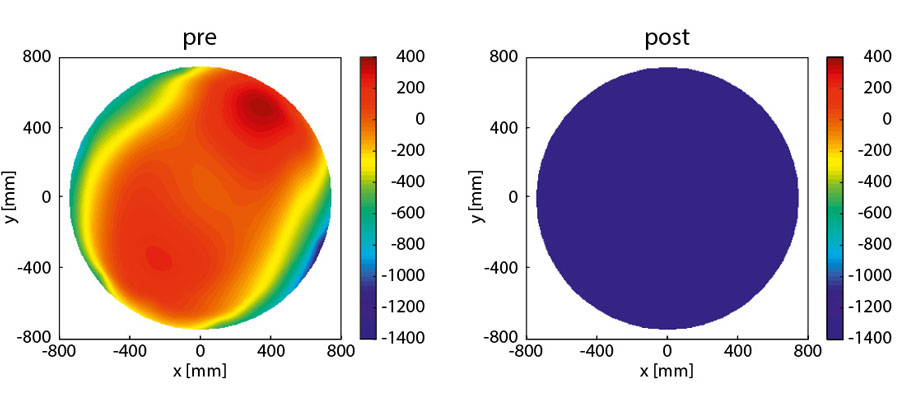

- Focused broad ion beam scans across wafer surface

- Amount of local material removal is controlled by adjusting the dwell time

- Vertical setup allows for low contamination

Features and Benefits:

- Long term, stable process for repeatable trimming/figuring of optical components

- Excellent precision on large areas

- High removal rates for high throughput

- Easy loading of large substrates enabled by sliding doors

- High volume production

- Short pumping down times

Applications:

Technical Specifications:

| SPECIFICATION | DESCRIPTION |

|---|---|

| Substrate size | up to 1500 mm diameter 400kg |

| Axes motor | Maximum velocity 0.15 m/s Maximum acceleration 15 m/s² |

| Ion beam source | 37 mm circular RF source (RF37-i) with 7-15mm (FWHM) 120mm circular RF source (RF120-i) with 16-36mm (FWHM) |

| Neutralizer | RF plasma bridge neutralizer (N-RF) |

| Typical removal rate | SiO2: RF37-i ~ 14 mm3/hr RF120-i ~ 96 mm3/hr |

| Film variation after trimming | < 0.5 nm RMS (dependent on input quality) |

| Base pressure | < 1 x 10-6 mbar |

| System dimension (W x D x H) | 3.60 m x 7.70 m x 3.40 m (without electrical rack and pumps) |

| Configurations | Single chamber with sliding doors, manual loading with transport cart, 3- or 4-axis control system for ion beam motion |

| Software interfaces | SECS II / GEM, OPC |