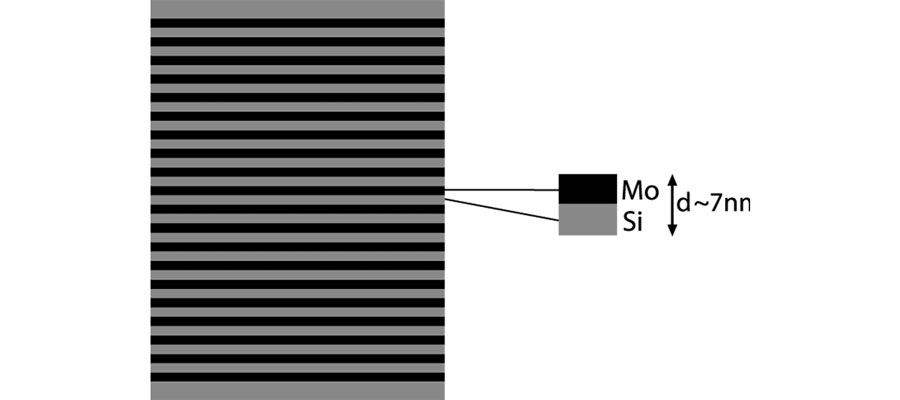

The scia Multi 300 / 400 / 500 / 680 / 1500 series are magnetron sputtering systems used for high-quality periodic multilayer coatings.

The scia Multi 300 is designed for wafers up to 300 mm and can be equipped with up to 4 magnetrons, enabling high-precision multilayer stacks of up to 4 target materials without breaking the vacuum. It is possible to deposit metals, oxide and nitride layers. The cassette load lock with automatic substrate transfer and system control ensures a completely automatic and recipe-controlled process.

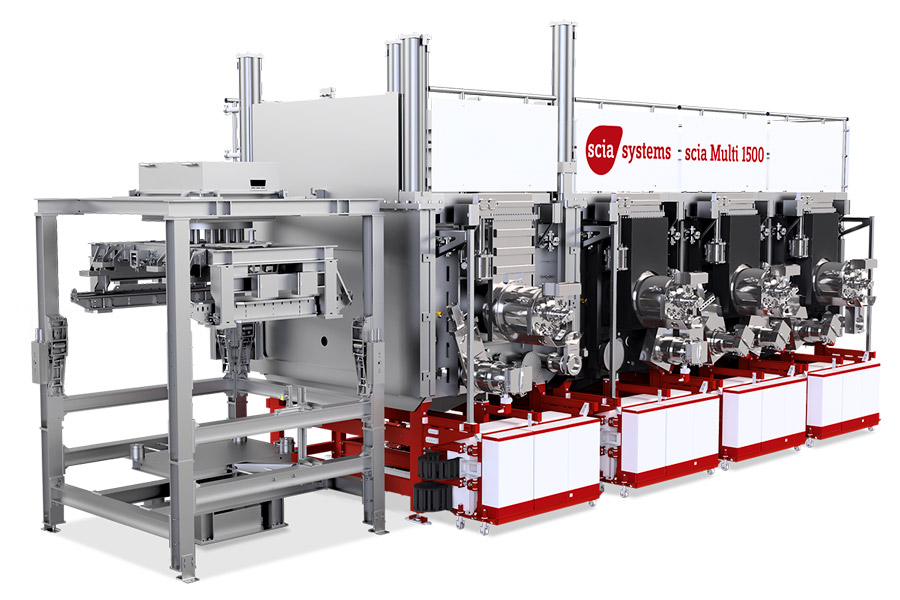

The scia Multi 680 and 1500 are designed for periodic multilayer coatings on curved substrates up to 680mm and 1500mm in diameter, respectively. It is capable of precisely depositing homogeneous or gradient films over multiple 100 multilayer periods.

Principle:

- The scia Multi 300 and 680 have a circular substrate movement across magnetrons. One orbital rotation completes one period of the stack. (Left and center video)

- The scia Multi 1500 has a linear arrangement of multiple process chambers, buffer chambers, and loading chambers that allows for a highly flexible tool configuration and high throughput.

It has an “inline” arrangement with 4 magnetrons per process module, with substrate rotation. (Right video)

Features and Benefits:

scia Multi 300

- Excellent uniformity over 300 mm substrate area

- Synchronized orbital and spin rotation for uniform multilayer films on wafers

- 4 magnetrons, each with individual gas supply and shutter unit

- Automatic cassette handling system with load lock

- Substrate face-down orientation for minimized particle load

scia Multi 680

- Homogeneous or gradient films on curved substrates by synchronized orbital and spin rotation

- Carrier based handling system with load lock and two independent substrate positions

- Up to 7 magnetrons, each with separate housing for individual gas supply and defined particle emission profile

- Optional substrate pretreatment with additional ion beam source

- Substrate face-down orientation for minimized particle load

scia Multi 1500

- Homogeneous or gradient films on curved substrates by synchronized linear movement and spin rotation

- Inline arrangement with multiple process and buffer chambers for complete crossing over the magnetrons

- 4 magnetrons in each process chamber

- Optional pretreatment with additional ion beam source

- Substrate face-down orientation for minimized particle load

Applications:

Technical Specifications:

| Multi 300 | Multi 680 | Multi 1500 | |

|---|---|---|---|

| Substrate size | up to 300mm dia. | up to 680mm dia., 130kg | up to 1500mm dia., 850kg |

| Sputter source | 4 rectangular magnetrons (400mm x 90mm) | up to 7 rectangular magnetrons (600mm x 90mm) Optional: Ion beam source for pretreatment | 4 rectangular magnetrons (1200mm x 90mm) per chamber Optional: Ion beam source for pretreatment |

| Sputter modes | DC in cw or pulsed mode (1 kW), and/or, RF (1 kW, 13.56 MHz) | DC in cw or pulsed mode (1 kW), and/or, RF (1 kW, 13.56 MHz) | DC in cw or pulsed mode (6 kW), and/or, RF (6 kW, 13.56 MHz) |

| Typical deposition rate | Cu: 43 nm/min Co: 26 nm/min | Cr: 45 nm/min Si: 22 nm/min Ti: 22 nm/min | Si: 48 nm/min Mo: 78 nm/min |

| Uniformity variation | < 0.6 % (σ/mean) over 300mm dia. | < 0.1 % (σ/mean) over 300mm dia., < 0.2 % (σ/mean) over 450mm dia. | < 0.5 % (σ/mean) over 1200mm dia. |

| Wafer throughput | NA | 12 Wafers/hr (100nm SiO2 removal on 200mm wafer) | 12 Wafers/hr (100nm SiO2 removal on 200mm wafer) |

| Base pressure | < 8 x 10-8 mbar | < 1 x 10-8 mbar | < 2 x 10-8 mbar |

| System dimension (W x D x H) | 3.60m x 2.70m x 2.30m (without electrical rack and pumps) | 7.90m x 4.40m x 3.50m (without electrical rack and pumps) | 11.00m x 4.20m x 5.00m (for 1 process chamber) (without electrical rack and pumps) |

| Configurations | Single chamber with cassette load lock | Single chamber with double substrate load lock | Inline system with multiple coating chambers and 2 buffer chambers, with single substrate load lock Optional: loading and balancing stage |

| Software interfaces | SECS II, OPC | OPC | OPC |